close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-12-09 Origin: Site

Grade | Width (mm) | Thickness (mm) | Length (mm) |

|---|---|---|---|

CRGO-27Q110 | 940–1010 | N/A | N/A |

AISI Silicon | 600–1100 | 0.35–0.5 | 2–5 |

Grain-oriented silicon steel is great for transformers. It has high magnetic permeability and low energy loss. Pick this type for transformer cores that work well.

Non-grain-oriented silicon steel is good for motors and generators. It gives the same magnetic properties in every direction. This makes it good for spinning magnetic fields.

When you pick electrical steel, look at core loss, thickness, and frequency. These things affect how well your electrical devices work.

Always check the magnetic properties and silicon content in the steel. More silicon means less iron loss and better magnetic performance.

Use the right steel grade for what you need. Grain-oriented steel is best for transformers that need to save energy. Non-grain-oriented steel is better for motors and generators in factories.

There are two main groups of electrical steel. One group is grain-oriented electrical steel. The other group is non-grain-oriented electrical steel. Each group has its own features. They are used for different electrical machines. Knowing these differences helps you pick the right grades for your project.

Grain-oriented electrical steel has grains that go in one direction. This makes it great for transformer cores. It has high magnetic permeability and low energy loss. Manufacturers use a special process to line up the grains. This helps transformers work better.

Note: Grain-oriented electrical steel is best for transformer cores because it has low core loss and high efficiency.

Some common grades are:

M-2, M-3, M-4, M-5, M-6 (North American system)

23QG, 27QG, 30QG (Chinese system)

Type of Silicon Steel | Typical Applications | Grain Structure |

|---|---|---|

Grain-Oriented (GOES) | Power transformers, Distribution transformers | Aligned in a single direction |

Grain-oriented electrical steel grades usually have about 3% silicon. This makes the steel resist electricity better. It also lowers eddy current losses. For example, 3% silicon can cut eddy current losses by almost 80% compared to plain iron. The core loss in grain-oriented electrical steel is usually between 1.2 and 1.5 W/kg. This is much lower than regular iron.

Grain-oriented electrical steel grades are made with a process that lines up the crystals.

This gives better magnetic properties in one direction.

You get less energy loss, so transformers work more efficiently.

Non-grain-oriented electrical steel has grains that point in many directions. This gives the same magnetic properties in every direction. These grades are used in motors, generators, and other machines with rotating magnetic fields.

Some common grades are:

M-15, M-19, M-22, M-27, M-36, M-45, M-47 (North American system)

M250-35A, M270-35A, M300-35A (European system)

Characteristic | Description |

|---|---|

Grain Structure | Randomly spread out, so magnetic performance is the same in all directions. |

Isotropy | Works the same way in every direction, good for rotating magnetic fields. |

Workability | Great for fast punching and making complex shapes. |

Efficiency | Makes motors quiet and saves energy. |

Applications | Used in industrial motors, generators, and new energy vehicle drive motors. |

Non-grain-oriented electrical steel grades also have silicon, usually between 2% and 4.5%. The silicon helps in many ways:

It makes the steel resist electricity more, so eddy current losses go down.

It lowers magnetic anisotropy and magnetostriction.

More silicon means less iron loss, especially at high speeds.

The size and shape of the grains also affect core losses, which is important for fast motors.

Non-grain-oriented electrical steel grades are best for machines with rotating magnetic fields. These grades are efficient, quiet, and easy to shape for complex parts.

It is important to know about magnetic properties when picking silicon steel for electrical devices. These properties help you choose the right grade for your needs. High magnetic permeability means you can make strong magnetic fields using less energy. Low hysteresis loss means less energy is wasted when the steel changes its magnetization. Good electrical resistivity helps stop eddy current losses, which makes the device work better.

Property | Description |

|---|---|

High Magnetic Permeability | Makes strong magnetic fields and saves energy. |

Low Hysteresis Loss | Wastes less energy when the magnet changes, so it works better. |

Excellent Electrical Resistivity | Stops eddy current losses, which is important for electrical devices. |

Magnetic properties are different for each grade and depend on how the steel is made. For example, waterjet cutting can make magnetic permeability better and lower energy loss. If you want motors and generators to work well, pick grades with high permeability and low coercivity.

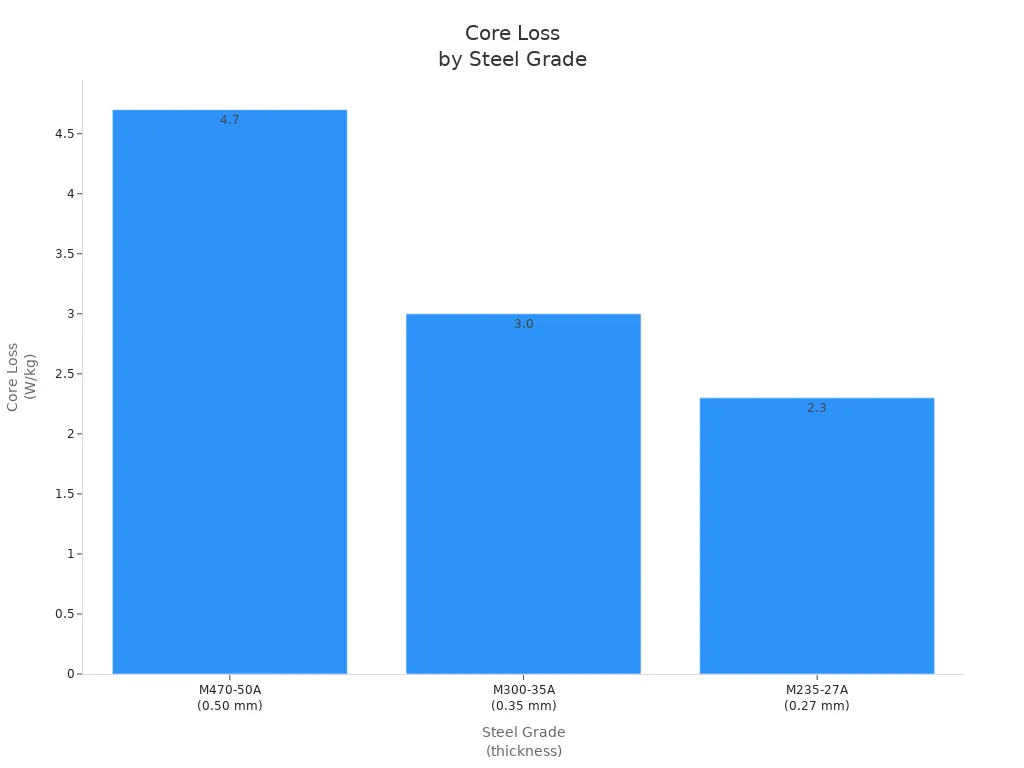

Efficiency and core loss are important when you pick silicon steel for your project. Core loss is how much energy turns into heat when the steel works. Lower core loss means the steel is more efficient. You can look at the core loss numbers and other magnetic properties to compare grades.

Grade (thickness) | Core loss P1.5/50 (W/kg) | B50 (T) | Hc (A/m) | Resistivity (µΩ·m) | Yield strength (MPa) | Lamination coating | Cost index* |

|---|---|---|---|---|---|---|---|

M470-50A (0.50 mm) | 4.7 | 1.70 | 35 | 0.47 | 420 | C3/C5 | 1.00 |

M300-35A (0.35 mm) | 3.0 | 1.75 | 30 | 0.48 | 480 | C5 | 1.12 |

M235-27A (0.27 mm) | 2.3 | 1.80 | 28 | 0.50 | 520 | C5/C6 | 1.22 |

Tip: To get better efficiency, pick grades with lower core loss and higher resistivity.

Silicon steel is used in many electrical machines. Grain-oriented silicon steel is best for transformer cores. Non-grain-oriented silicon steel is good for motors and generators because it has the same magnetic properties in every direction. You should pick the right grade for your machine to get the best results.

Application Type | Silicon Steel Grade |

|---|---|

Power Transformers | Oriented Silicon Steel |

Distribution Transformers | Oriented Silicon Steel |

Industrial Motors | Non-oriented Silicon Steel |

Power Generators | Non-oriented Silicon Steel |

AC Alternators | Non-oriented Silicon Steel |

Type of Silicon Steel | Common Applications | Preferred Grade Specifications |

|---|---|---|

Grain-Oriented Silicon Steel | Power transformers, Distribution transformers, Ballast transformers, Instrument transformers, Audio transformers, Specialty transformers | Operating inductions: 10,000 to 17,000 G, Power ratings: 500 to 1,000,000 kVA |

Non-Grain-Oriented Silicon Steel | Industrial motors, Power generators, AC alternators | Lower magnetic permeability, good for low-power machines |

Grain-oriented silicon steel is used in high-efficiency transformers and special transformers.

Non-grain-oriented silicon steel is best for motors, generators, and alternators.

You will find non-grain-oriented grades in small motors and electronic devices.

Note: Always check the magnetic properties and efficiency before picking a grade for your machine.

If you want to build transformers, motors, or generators, you need to know about electrical silicon steel sizes. The size you pick can change how well your device works. It also makes building easier or harder. There are many choices for thickness, width, length, and format. Let’s talk about the most common sizes and shapes you will see.

Electrical silicon steel comes in a few standard thicknesses. The thickness you choose can make your machine work better or worse. Thinner steel usually means less core loss. It also gives better magnetic properties. Both grain-oriented and non-grain-oriented types come in different thicknesses.

Category | Thickness (mm) | Silicon Content (%) | Application |

|---|---|---|---|

Hot Rolled High Silicon Steel | 0.35, 0.50 | 3.0~4.5 | Transformer |

Cold Rolled Electrical Steel | 0.50, 0.65 | ≤ 0.5 | Small transformers |

Grain-Oriented Electrical Steel | 0.23, 0.27, 0.30, 0.35 | 2.8–4.8 | Transformer cores |

Non-Oriented Electrical Steel | 0.20, 0.35, 0.50, 0.65 | <2.8 | Motors, generators |

Oriented silicon steel often uses thicknesses like 0.23 mm, 0.27 mm, and 0.35 mm. Non-oriented silicon steel comes in thicknesses from 0.20 mm up to 0.65 mm. These choices help you pick the right steel for your job. You can choose high efficiency or lower cost.

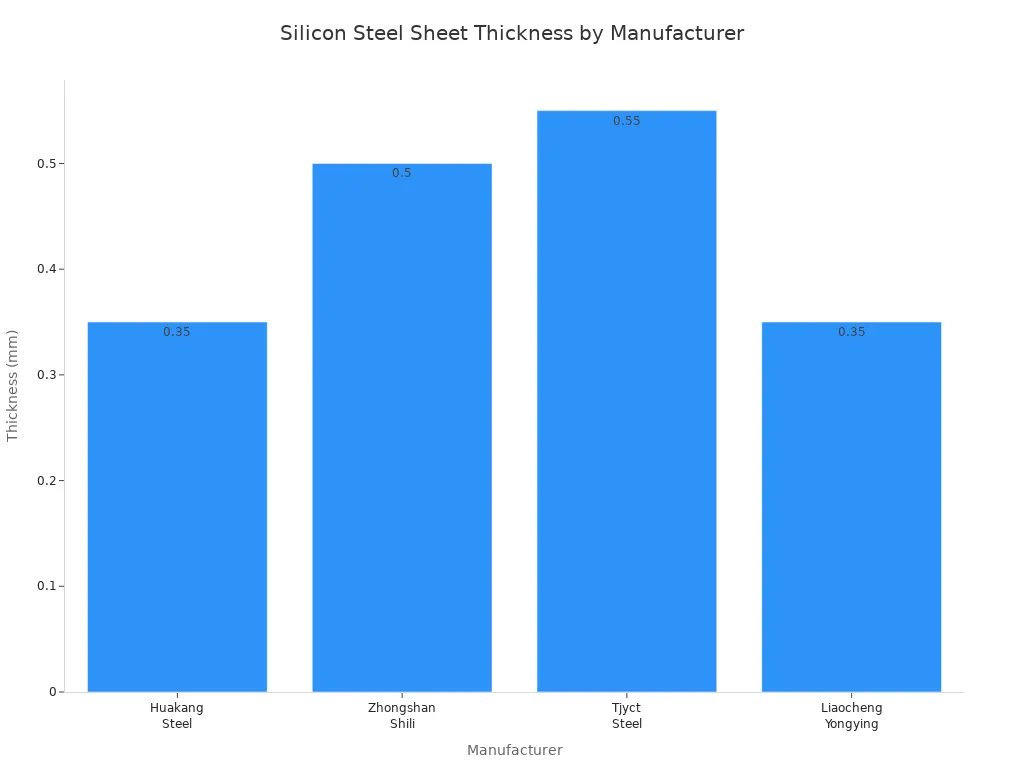

You should know the usual widths and lengths for electrical silicon steel. These sizes help you plan your work and make sure parts fit. Most suppliers have many options. You can also ask for special sizes.

Specification | Value |

|---|---|

Thickness | 0.35 mm |

Width | 20 mm - 1250 mm (customizable) |

Length | 200 mm - 3000 mm (fixed sheets) |

Dimension | Range |

|---|---|

Width | 1000 mm–1500 mm |

Thickness | 0.3 mm–16 mm |

Inner Diameter | 508 mm or 610 mm |

Weight | 3–25 tons |

Transformer cores and motor laminations use sheets and strips with widths from 800 mm to 1050 mm. The most common coil inner diameter is 508 mm. This matches many factory standards. You can order sheets with fixed lengths from 200 mm to 3000 mm. These choices make it easy to find the right size for your project.

Thickness (mm) | Width (mm) | Length (m) |

|---|---|---|

0.35 | 800-1000 | ≤ 2.0 |

0.50 | 800-1000 | ≤ 2.0 |

0.65 | 800-1000 | ≤ 2.0 |

Tip: Always check the rules for coil sizes. Most coils have an inside diameter of 508 mm. The outside diameter can be up to 1850 mm.

You can buy electrical silicon steel in different shapes. Each shape has its own good points for building and working. The most common shapes are sheets, coils, and strips.

Product Format | Description | Impact on Manufacturing |

|---|---|---|

Sheets | Thin, laminated sheets designed to minimize eddy current losses. | Enhances efficiency in electrical devices. |

Coils | Rolled silicon steel that can undergo specific annealing processes. | Optimizes magnetic characteristics and electrical performance. |

Strips | Narrow strips of silicon steel for specific applications. | Tailored for particular manufacturing needs. |

Sheets are great for transformer cores and motor laminations. You can stack them to lower energy loss.

Coils let you use lots of steel and add heat treatments to make magnetic properties better.

Strips are good for custom shapes and small parts in motors or generators.

Oriented silicon steel is usually sold as sheets or coils for transformer cores. Non-oriented silicon steel is often sold as strips for motor and generator laminations. The shape you pick can change how much energy your device uses.

Note: Keeping the silicon content just right in these shapes gives strong magnetic induction and low eddy current loss. This helps you save energy and cut down on pollution when making things.

You can also get electrical silicon steel in laminations. Laminations are thin layers stacked together. They help lower core losses in motors and transformers.

Transformer cores

Silicon steel sheets

Laminations

When you pick electrical silicon steel sizes, think about the shape, thickness, width, and length. These choices help your transformer, motor, or generator work its best. Oriented silicon steel is best for high-efficiency transformers. Non-oriented silicon steel works well for motors and generators.

When you pick electrical silicon steel, you should think about six main things. These things help you choose the best steel for your job. It does not matter if you work with transformers or motors. The table below shows how each thing can change your choice:

Criterion | Influence on Material Choice |

|---|---|

Target core loss | Decides how much energy is lost and how efficient it is. |

Magnetization direction | Changes how well it works with one-way or spinning fields. |

Required thickness | Affects the size and weight of your machine. |

Operating frequency | Changes how the steel works at different speeds. |

Mechanical processing needs | Decides how easy it is to make and shape the steel. |

Price vs. performance balance | Helps you pick a steel that is not too expensive but works well. |

You should always make clear rules before you pick a grade. Think about how much core loss you want. Decide which way the magnetization should go. Pick the thickness you need. Check the speed your device will run at. Make sure the steel is easy to use in your factory. Try to get good performance without spending too much money.

You can use these steps to help you choose:

Check the speed your device will run at. Pick a grade that works for your motor or transformer.

Think about how much energy loss you can allow. Choose a grade that saves energy.

Measure how strong the magnetic field should be. Pick steel with the right permeability.

Look at how you will make your product. Make sure the steel fits your machines.

Think about your budget. Choose a grade that you can afford.

Many people make mistakes when picking silicon steel. You can avoid these problems if you follow these tips:

Do not forget about the environment. Pick steel that can handle stress and does not rust easily.

Make sure the steel’s electrical properties fit your needs. This helps your machine work better.

Do not pick cheap steel if it will not last long. Think about how well it will work over time.

Check if the steel works well with other parts. This stops problems later.

Use more than one supplier. Stay in touch with them to avoid running out of steel.

You can use these tips for common uses:

Application | Recommended Grade |

|---|---|

Power transformers | Use high-grade grain-oriented or CRGO (23QG, M0H, M2H) |

Industrial motors | Use low-loss non-oriented silicon steel (35W300, 20W270, M19 NGO) |

Generators | Use high-grade non-oriented silicon steel for steady power and low heat |

Home appliances | Use low-loss non-oriented silicon steel for quiet and efficient work |

Tip: Always pick the grade that matches your job. This helps you save energy and get better results.

You can easily tell the difference between grain-oriented and non-grain-oriented silicon steel grades. Grain-oriented steel works best in just one direction. This makes it great for transformers. Non-grain-oriented steel works the same in every direction. That is why it is used for motors and generators. When you look at different grades and sizes, you can make better choices for your project. You should pick steel with low iron loss, high magnetic sensitivity, and good insulation.

Feature | Grain-Oriented Steel | Non-Grain-Oriented Steel |

|---|---|---|

Magnetic Direction | One direction | All directions |

Main Use | Transformers | Motors, Generators |

Cost | Higher | Lower |

More silicon in the steel means less iron loss and better magnetic properties.

Always check dielectric strength, resistivity, and operating voltage before you decide.

Electrical steel is used to make machines with magnetic fields. You see it in transformers, motors, and generators. This steel helps save energy and makes machines work better. It also helps machines last longer.

Silicon steel has silicon inside. This makes electrical resistance higher. It lowers core loss and gives better magnetic properties. Devices with silicon steel stay cooler and use less energy. That is why silicon steel is a good choice for electrical steel.

Pick grain-oriented electrical steel for transformer cores. This grade has high magnetic permeability and low core loss. Silicon steel in grain-oriented grades helps transformers work well and waste less energy.

You can buy electrical steel and silicon steel as sheets, coils, or strips. Thicknesses are usually from 0.20 mm to 0.65 mm. Widths are often between 800 mm and 1250 mm. Choose the size that fits your project.

Yes, non-grain-oriented electrical steel works for motors. It gives the same magnetic properties in every direction. Silicon steel in these grades helps motors run quietly and efficiently.

Tip: Always pick the electrical steel grade and silicon steel content that matches your project for the best results.

Application | Electrical Steel Type | Silicon Steel Benefit |

|---|---|---|

Transformers | Grain-oriented | Low core loss |

Motors | Non-grain-oriented | Quiet, efficient operation |

Generators | Non-grain-oriented | Consistent performance |