-

Online ultrasonic testing

Online ultrasonic testing -

Online ultrasonic testing

Online ultrasonic testing -

Laboratory iron loss test

Laboratory iron loss test -

Laboratory iron loss test

Laboratory iron loss test -

Surface inspection

Surface inspection -

Surface inspection

Surface inspection -

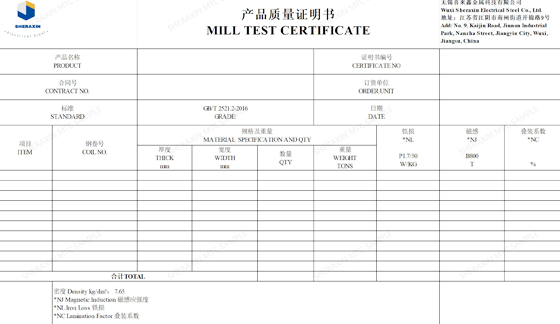

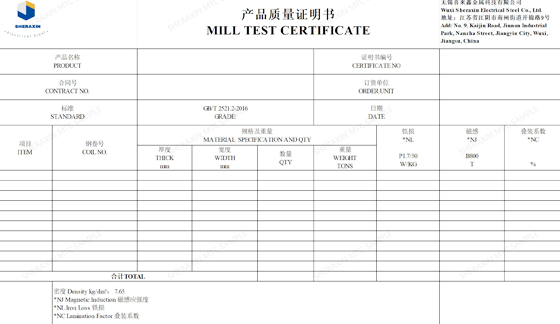

MTC Sample_Sheet

MTC Sample_Sheet -

Weighting before loading

Weighting before loading -

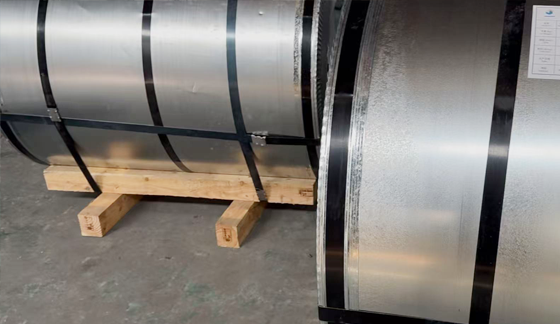

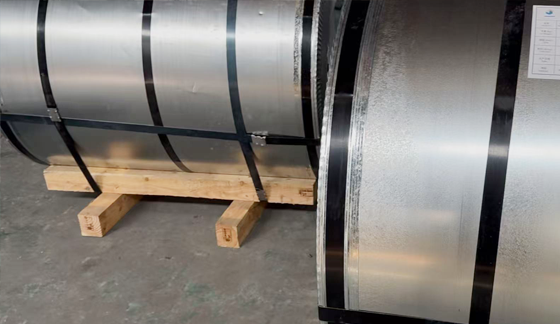

Packing and marking inspection

Packing and marking inspection

close

Choose Your Site

Global

Social Media